If you need six sigma implementation advice, please contact our experts at Modirfa.

02188764867 – 02188761795

Six Sigma Consulting

Six Sigma is a concept that seems familiar to many managers, but what is Six Sigma? Our experienced experts in the field of quality engineering will explain this concept clearly for you. In general, six sigma is an approach to improve the organization’s processes in terms of cost, quality and time. If you are looking to make dramatic improvements in your organization, Six Sigma is the best choice for you.

Implementation of Six Sigma

What is Six Sigma?

Six Sigma approach It is process-oriented and data-oriented for problem solving. that this approach is related to a specific domain Is not. In other words, six sigma finds and solves any problem, whether small or big, whether in the organization or in life, whether in production or in services. Most of the problems of the organizations show themselves in the majority of costs, customer dissatisfaction, low work cycle, etc.

Six Sigma based on certainty

As mentioned, Six Sigma is data driven and speaks to you based on certainty. Unlike most management tools that solve problems based on assumptions and assumptions, Six Sigma reliably 95% for the organization identifies issues and span, and then solves them.

If you see that your organization has moved away from the point of view of your customers, or the ideas of your managers are not working to solve a problem, or you even feel that there is a problem and you don’t know where the root is, Noor Consulting Engineers Group (Modirfa), which is one of the most established Companies that develop and improve quality systems recommend Six Sigma to eradicate these problems.

The importance and impact of six sigma implementation

The goal of Six Sigma

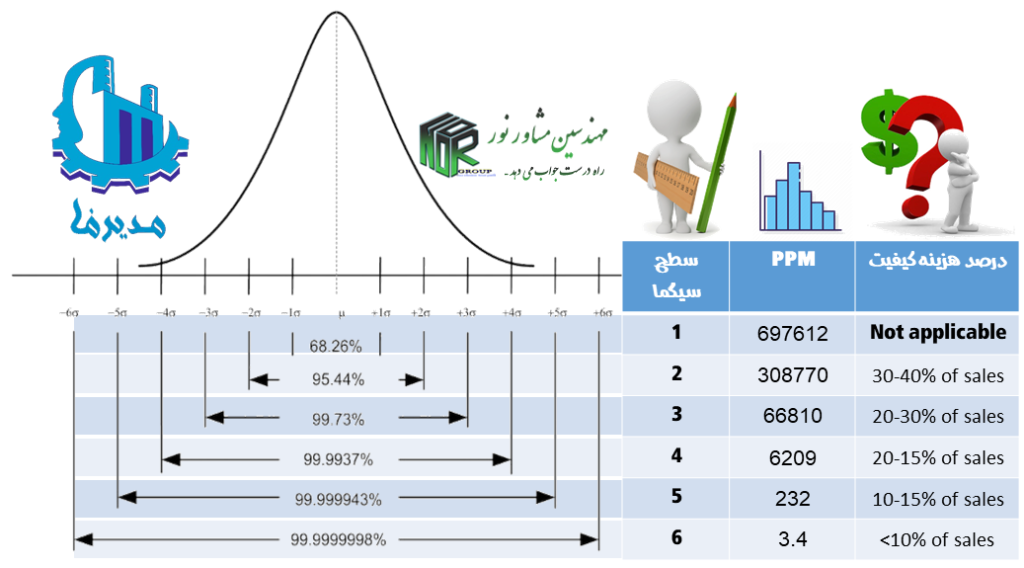

The goal of Six Sigma is to increase the probability of the product matching the customer’s demand 99.99966 It’s a percentage, you might say 99 The percentage is enough, but it is enough for you to consider the hospitals of a country, which have at least approx 1Millions of surgeries are performed , by multiplying this probability in a surgery by a number We get 999,000, this is the number of safe and error-free surgeries in hospitals and 110,000 Surgery is done with errors that completely lead It leads to the death of people. But only at the six sigma level 3.4 surgical procedures lead to errors.

Sigma levels

Sigma gives us a concept of dispersion. In the six sigma approach, the purpose of using the concept of sigma level is to express how much a process can have dispersion in its outputs without causing customer dissatisfaction. So according to the definition, the higher the sigma level, the more accurate the process works.

Effects of Six Sigma

Levels such as 3 sigma of dispersion in production and services consume a share of about 25 to 40 percent of your organization’s income and turn it into costs to compensate for losses, and this depends on the organization’s actions and projects for have made improvements, otherwise the organization will undoubtedly not reach 2 sigma levels. This is despite the fact that the Six Sigma level wastes less than 1% of your organization’s costs. Reducing the cost of producing quality products in order to make the organization as profitable as possible and increase customer satisfaction and gain more market share has always been the main concern of Noor Consulting Engineers Group, for this we will be with you until the end of the road.

Benefits of implementing Six Sigma

Reduce operating costs

Increase efficiency

Increasing the accuracy, control and compliance of policies

Increased cash flow

Increase customer service

Improving compliance with organizational regulations

And in a simpler language to discover the hidden mines of money among the processes

At the internal level, projects such as Arak Machinery could save 35% of its costs by increasing only 19% of the sigma level of its process. Please note that this organization was able to achieve such success by correcting only one process.

DMAIC is the weapon of Six Sigma

Six Sigma uses a process-oriented approach to problem solving, including 5 phases: Define, Measure, Analyze, Improve, and Control.

Define

In this phase of the implementation of the Six Sigma methodology, the Six Sigma deployment team defines the problem and real needs of the customer and tries to convert the needs into functional processes in the organization.

Measure

The purpose of doing this phase is to bring all the assumptions of the process to certainty, by collecting data and performing hypothesis tests, you can get the knowledge of what state the organization is in, based on which you can plan for improvement.

Analyze

Six Sigma is a data-based problem solving method, the data we receive from the process are worthless to us at the beginning without analysis, but these same data reveal hidden gaps in the process after performing various statistical analyzes. We find that it creates sources of money in the organization.

Improve

In the improvement phase, by applying well-known engineering and quality management methods, we repair the gaps found in the process and minimize waste and inconsistent outputs.

Control

By leaving any system, however highly efficient, to itself, it causes its efficiency to decrease over time and begin to produce non-conforming products again, so it is an integral part of any process to control it.

Six Sigma Consulting

In the end, six sigma not only has amazing results in terms of finances for the organization, but also reduces the rate of layoffs and layoffs to the minimum possible per year, and also creates a rich culture in the organization that encourages the thinking of all members of the organization for continuous improvement and development. The organization engages with itself.

Services provided by Noor consulting engineers group in six sigma deployment projects

Based on the experiences gained in the group of Noor Consulting Engineers, every process in the organization has a potential level that most organizations do not operate at this level. This vacuum is caused by some factors (operator, device, environment, etc.).

Being lean in the industry means doing activities and processes without any waste. In general, the organization’s activities fall into three categories, activities that add value and create value for the customer, activities that are needed for the organization and actually create value for the organization, and finally activities that have no value for the organization. Customers and organizations do not create

Process design with six sigma approach

To compete, it is necessary to rely on a new process that can satisfy the needs of the organization and the customer. Noor consulting engineers group with a rich history of establishing quality management systems and improving them confirms this statement.

In today’s competitive markets, improvements can only be made by creating value for the customer. As time goes on, I can see that our needs are changing and organizations are meeting them.

To implement and run a business, whether in the field of production or services, it is necessary to make detailed plans on the expected processes of the organization, so that after the establishment of the organization, it can be used optimally.

The implementation phases of the six sigma consulting project in Modirfa

zero phase

The implementation of six sigma in its zero step includes holding opening meetings to identify the owners of the processes, introducing six sigma and its approaches, and further empowering the organization’s personnel in the implementation of the project.

The purpose of implementing this phase is to strengthen the human capital of the organization for the continuation of the project, which is provided by the consultants of this field, the necessary training.

The first phase – definition

In this phase, the goal is to identify and correctly define the problem, which can be considered the most important phase of six sigma implementation projects in the organization, because in this phase, the problem is defined, and if the problem is stated incorrectly, the entire phase The next ones are questioned.

The main activities of this phase include:

1- Identifying the complications of the organization in the 3 areas of time, quality and cost

2- Project planning (six sigma projects last 6 to 8 months from phase 1 to phase 5)

is.

The second phase – measurement

In the six sigma deployment process, the most time-consuming phase is usually assigned to this phase, because the data must be collected in such a way that it has both accuracy and indicates the entire input and output community of the organization.

The main activities of this phase include:

1- Identification of effective processes

2- Verification of data accuracy

3- Determining how to collect data

is.

The third phase – analysis

During Six Sigma implementation projects, the analysis phase is the most specialized phase in terms of having academic knowledge, in this phase, the collected data enters the analysis process, and its ultimate goal is to determine the impact of various factors on the output of the process.

The main activities of this phase include:

1- Process capability studies

2- Identification of effective factors

3- Conducting statistical studies

4- Identification of losses

is.

The fourth phase – improvement

Based on the outputs of the analysis process, in this phase, a set of solutions for improvement is prepared and presented. The final goal of this phase is to confirm and validate the implemented actions.

The main activities of this phase include:

1- Streamlining the process

2- reducing dispersion

3- Reliability studies

4- Designing tolerances

5- Acknowledgment and validation

is.

The fifth phase – control

Standardization and error-proofing of the process after implementing appropriate measures and preventing the process from returning to the state before improvement.

The main activities of this phase include:

1- Defining how to control the process

2- Performing periodic audits

3- Standardization

4- Review

is.

Most of the Six Sigma projects are carried out in the shortest possible time with the highest level of efficiency, provided that the project consultants are among the best in that field. Noor Consulting Engineers has been one of the pioneers in providing quality improvement and development services in large organizations since 2007. Iran has been the land that the company’s fruitful resume is proof of this, contact us to receive the company’s resume and six sigma implementation consultation.

Unlike most management approaches to solving organizational problems and issues, which are associated with guesswork and often do not provide the desired result, Six Sigma identifies the problem with certainty and brings the organization to the desired goal.

If you need six sigma implementation advice, please contact our experts at Modirfa.

02188764867 – 02188761795