Lean production implementation consulting

Contact our experts at Medirefa to get free advice on implementing lean production.

02188764867 – 02188761795

What is lean production?

One of the main concepts in the industry and in the principle of industrial engineering is the issue of lean production. The main idea of lean production is actually quite simple… it tries to eliminate the production process waste or Muda.

MUDA in Japanese means anything extra.

Lean manufacturing means creating more value for customers with fewer resources.

The important principle of lean is to reduce and eliminate activities without added value and waste.

What is waste?

Waste is defined as any activity that does not add value from the customer’s point of view. According to research conducted by the Lean Enterprise Research Center (LERC), fully 60% of the production activities in a typical manufacturing job are waste.

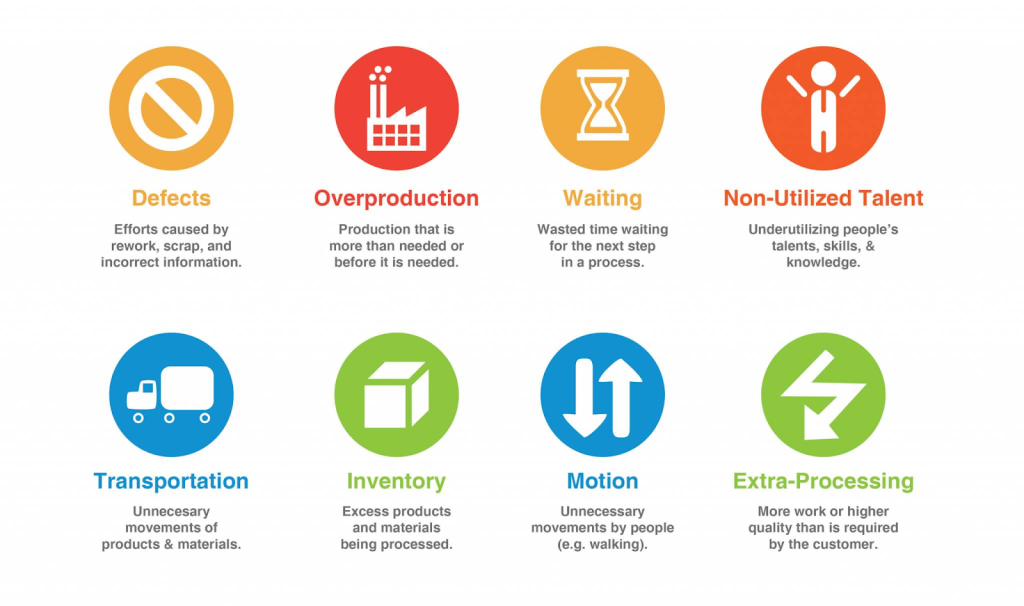

8 important wastes in lean production

- Deffects

- Overproduction (surplus production)

- Waiting

- Non-utilized talent(Untapped talent)

- Transportation(the transfer)

- Inventory

- Motion(Move)

- Extra-processing(Additional process)

Lean production consulting

Lean production consulting is possible in any type of production organization.

There are 25 important tools for lean manufacturing that businesses should consider, out of which some of them may be currently being implemented in their organization, or some of those tools may be needed for their organization as a whole. not practical

Therefore, for the implementation of lean production, it is important to first identify the tools that are suitable for the organization, and then prioritize the implementation, and if you need advice in this regard, be in touch with the modirfa consultants.

25 important tools of lean production

- 5s

- Andon

- Bottleneck analysis

- Continuous flow

- Gemba

- Heijunka

- Hoshin Kanri

- Jidoka

- Just-In-Time

- Kaizen

- Kanban

- KPI

- waste Muda Or Waste))

- Overall effectiveness or OEE

- PDCA

- Poka-Yoke

- Root Cause Analysis

- SMED

- Six lesions

- Smart goals

- Standard work

- Takt Time

- Comprehensive maintenance and repairs

- Value Stream

- Visual Factory

Implementation steps:

- Identification of losses

- Finding the right tools for the identified losses

- Identifying connections between tools

- Prioritizing the implementation of tools

- Performance

- Acknowledgment and validation of implementation

- improvement

Benefits of implementation:

- It reduces production costs while keeping the selling price constant

- Reduces delivery time, cycle time, setup time

- Eliminates waste

- Seeks continuous improvement

- Improves quality

- Improves customer satisfaction

- Employee engagement improves company morale and culture.

The implementation of lean production is possible in any type of organization, but the type of implementation depends on the organizational culture, the type of production, and the type of dominant waste in the organization. Consultation and implementation of lean production can improve quality and increase customer satisfaction along with reducing production costs and product prices.

Since 2007, Modirfa has the honor of implementing and implementing the lean production system in various industries, and you can contact our consultants if you need to implement the lean production system.

Noor Management Consultants contact numbers:

02188764867 – 02188761795

Contact our experts at Medirefa to get free advice on implementing lean production.

02188764867 – 02188761795