Contact our experts at Modirfa to get free advice on production planning.

02188764867 – 02188761795

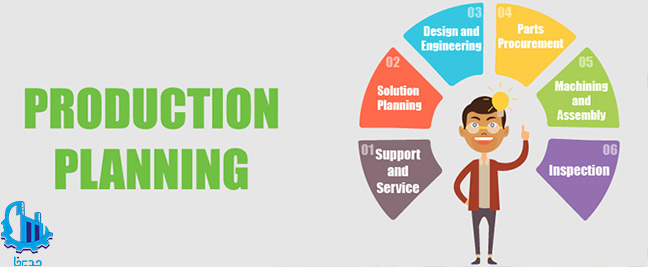

Production planning and management is more than maximizing the productivity of devices and equipment, preparing the optimal production plan and optimal use of resources requires an operational balance suitable for the organization.

But what is production planning and management?

Whether you are a new manufacturer oiling up your machinery for the first time or an old manufacturer producing thousands of items, production planning is a must. Similar to how scrum software and monthly schedules work, production schedules ensure optimal use of resources.

First, let’s understand the basic terms about production planning, see how it is done, look at common problems we should be aware of, learn about the types of production planning, and finally, some topics and solutions. Let’s review related to production planning.

In case of product production based on order (MTO), production orders or work orders are issued after receiving customer orders. A company pursuing make-to-stock (MTS) creates production orders depending on demand, market fluctuations, inventory, and the organization’s macro strategies. Production plans are usually planned by production managers or senior managers who monitor the market and sales situation. A good production schedule makes the best use of available resources to meet the needs and expectations as well as deliver the orders on time.

Why should we plan and manage our production?

Handling a few mass production orders is simple, but for large manufacturers, the complexity becomes enormous. Production planning also helps to plan the supply of raw materials based on the amount of final products produced. It also affects inventory, cash flow, sales and distribution. In addition, one of the most important resources of the organization, which is human power, is also optimized if there is production planning.

How to do production planning?

Five steps to plan and improve production planning: In the following, we point out five points that are essential for preparing production planning and improving their efficiency.

A) Demand forecast: Before production planning, the first step is to forecast product demand. Demand forecasting can be based on customer orders or based on inventory (two types of production organizations). Although this forecast may not be accurate to the last digit, the approximate allocation of needs is important for resource allocation. Forecasting can be done based on factors such as past data and market trends/demands. It should be noted that the science of statistics in the topic of predictive analysis is also useful in this topic. Drawing a proper forecast helps to plan the type and amount of raw materials needed, as well as planning for the procurement of raw materials.

b) Check the inventory: Both understocking and overstocking are undesirable situations. If there is a shortage, you cannot continue production, and if there is a surplus, you waste space and money. Effective inventory control includes reordering current inventory when it falls below specified levels and calculating supplier lead times for ordering items with long lead times, among other benefits of inventory control.

c) Plan for everything and all personnel: Often, when preparing production plans, some devices or some personnel are neglected. The issue here is that the machine might break down or the worker might be on vacation or worse, working on another product/device. Hence plan for each machine, raw material, workstation, warehouse and employees.

d) Monitor: After the finalization of the production plan and delivery of work orders, the production process begins. At this point, some programming things may go wrong, machines may stop, or an error may occur. Continuous monitoring of the operational layers of the organization with supervisors or with Internet of Things (IOT) devices ensures that all parts of the influencing factors in the production plan proceed according to plan.

e) Update and improvement: Despite your best planning, at the operational level, things do not go according to your plan. Anything can happen, from suppliers being late with raw materials to workers being absent and machines breaking down. It is very important to be flexible and adapt quickly to these changes so that planned quantities are delivered on time. Ideally, you should also plan ahead for such risks.

The above steps are the general steps required for production planning and management in organizations. Production planning is easily done with the right tools. By accurately allocating resources, planning inventory and avoiding mistakes, you can deliver your orders on time.

With a 13-year history since 1387, the management team has implemented a variety of management systems and methods required by industries in various industries. Also, the modirfa team is ready to provide production planning services and consulting to all production organizations with all kinds of production systems.

To request a consultation, you can wait for a call from the modirfa team by clicking on the consultation request and completing the requested information. Also, if you need to provide more information about the services that can be provided, you can contact us through the following numbers.

Contact our experts at Modirfa to get free advice on the implementation of production planning.

02188764867 – 02188761795

Beware of unlicensed and fraudulent organizations.

Be sure that if an organization gives you an ISO certificate without implementing it in your organization and conducting an audit, it must be a fraud.